Open Solutions

Traceability

Speed

Reliability

Transparency

Sustainability

Proactiveness

Flexibility

Our attitude, approach

and ambition make

our Open Solutions.

Our approach is to constantly explore new languages and develop a wide range of solutions that cater to each client's unique needs. This allows us to offer open solutions that are tailored to individual preferences.

It is the ability to industrialize our customers' requirements through a complete, structured and integrated production process.

It is the willingness to apply innovation in every choice with certified and sustainable supply, ensuring total traceability of the production chain.

Archive

–––––––––

Here we find inspiration for new collections, cues to solutions increasingly tailored to the customer and their needs as well as input on languages and patterns to reinterpret. Besides, this place reveals also our heritage, a history made of passion and avant-garde.

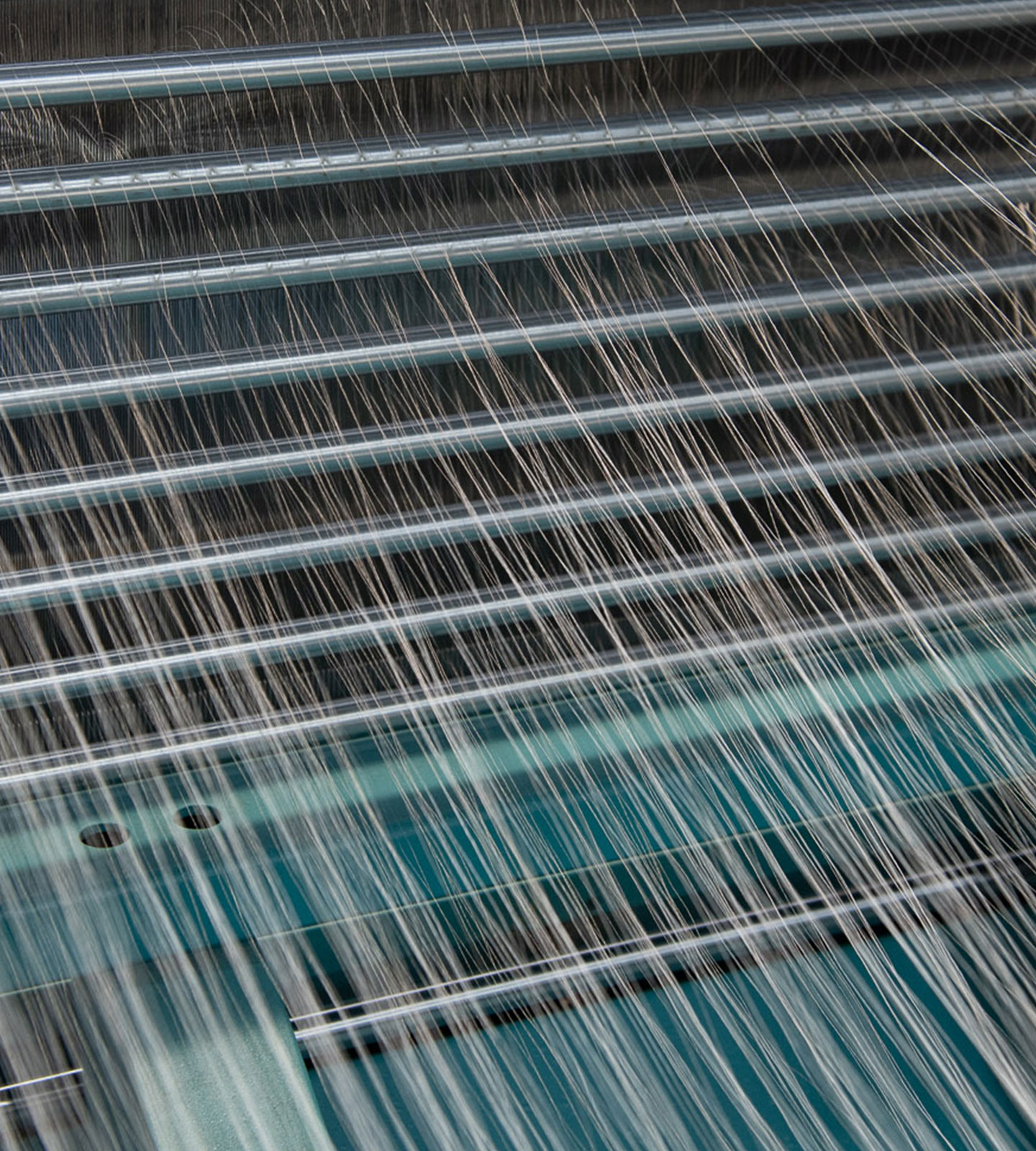

Weaving

–––––––––

Warp and weft, perpendicular and transverse yarns

are weaved on a loom to create magic and give life

to the creation of unique fabrics.

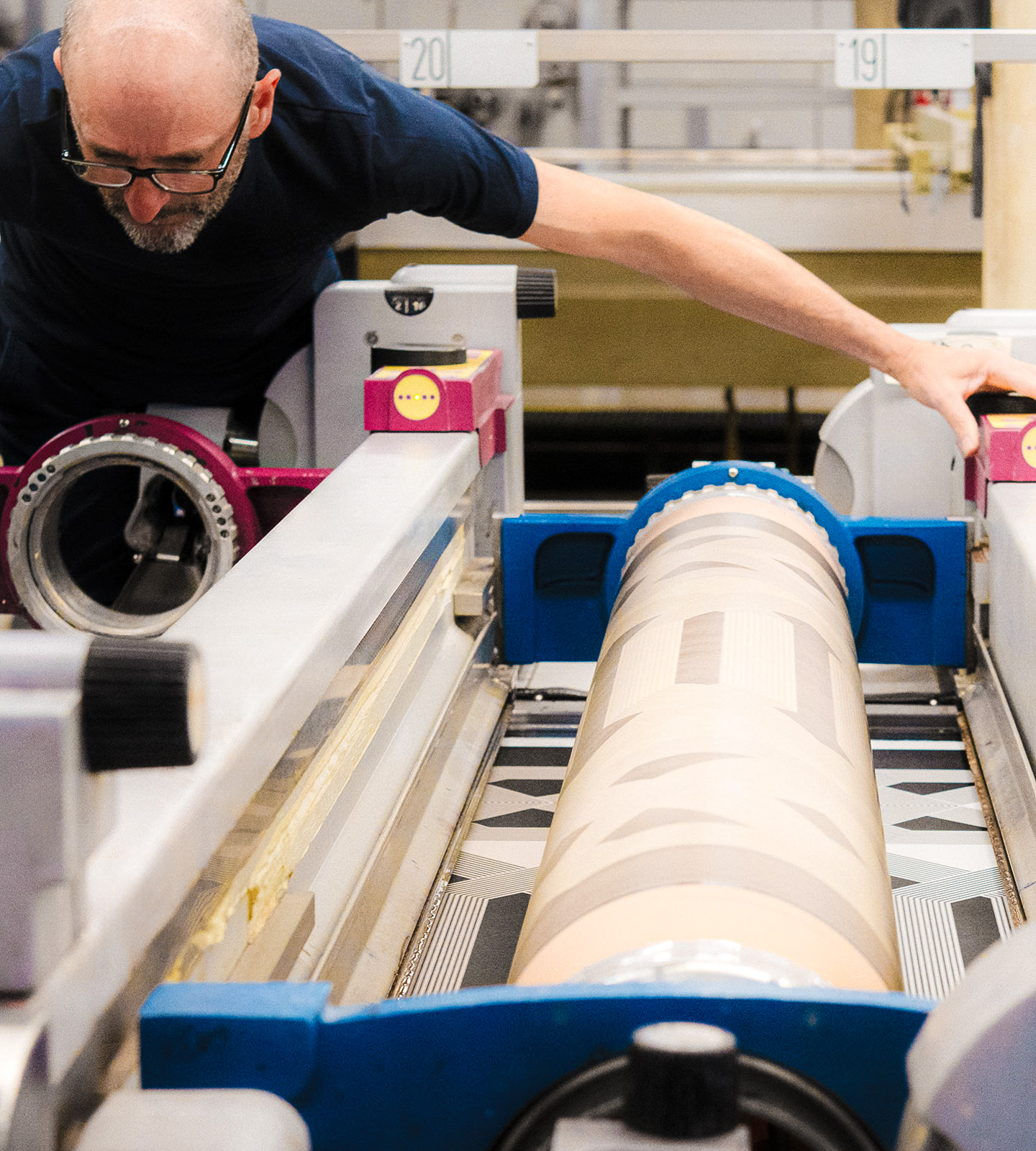

Rotary Printing

–––––––––

A traditional printing technique that is extremely functional when it comes to high volumes. Why? Because the fabric lies on a continuously moving carpet, which allows the cylinders to deposit the printing pastes colors on the fabric without metric limitation.

Ink-jet Printing

–––––––––

Ink-jet printing is innovative, versatile and effective. A digital method that allows us to customize any fabric with the design required by the customer to excellent results in color rendering and process speed.

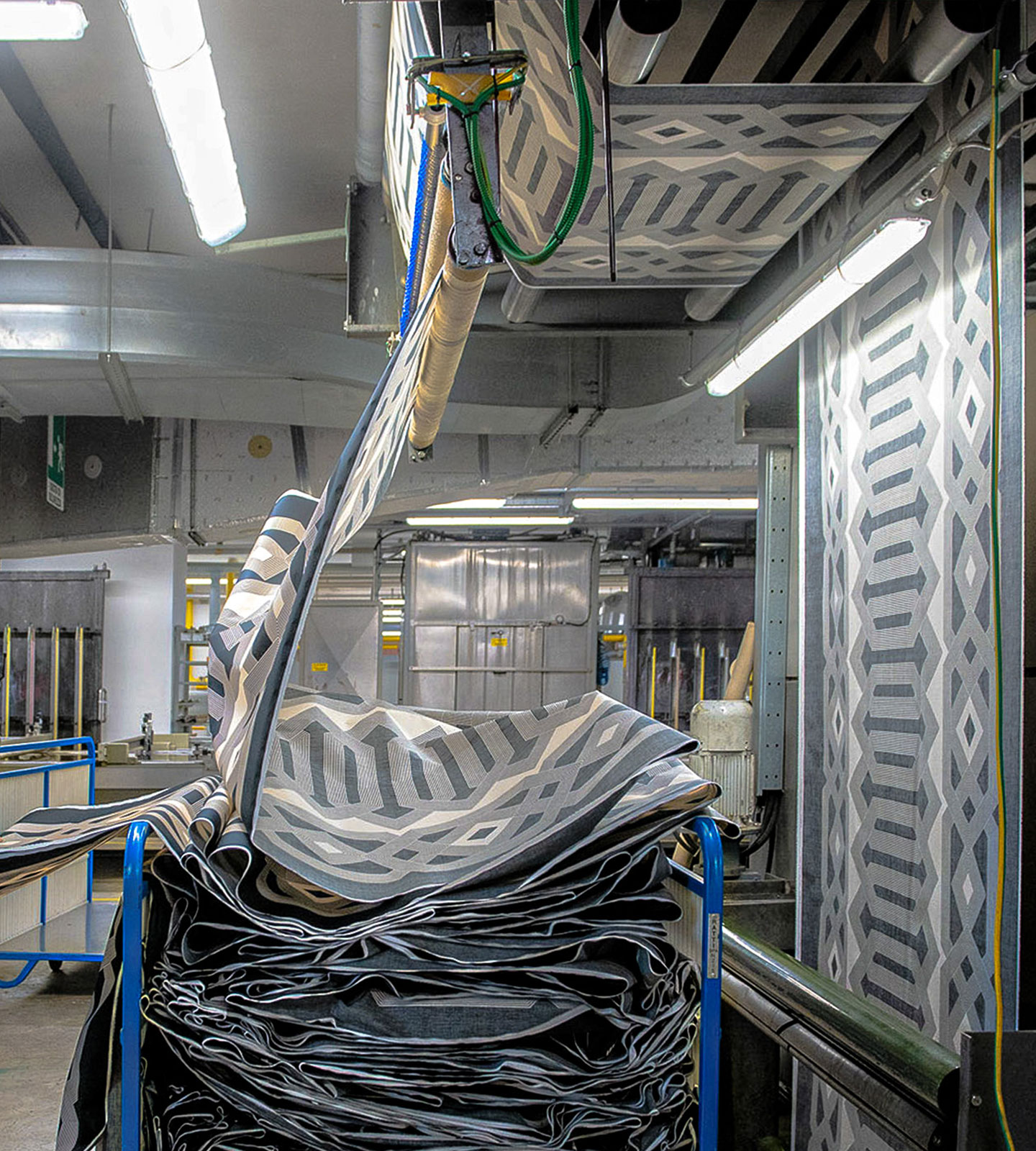

Finishing

–––––––––

It is at the steaming, washing and finishing stage that the fabric goes from raw to finished. We are almost at the end of the production process and the aim is to perfect the fabric. Our is a technique honed over the years that involves physical, chemical and mechanical treatments with one goal: to meet the demands of our customers

in terms of quality and service.

Quality Control

–––––––––

Quality control is an always-on activity throughout the process:

each team, according to its expertise, closely examines the fabric to immediately identify possible defects, whether of the yarn itself or derived from the production process and produce an item that

responds to the customer's requirements.